+8615954788872

+8615954788872

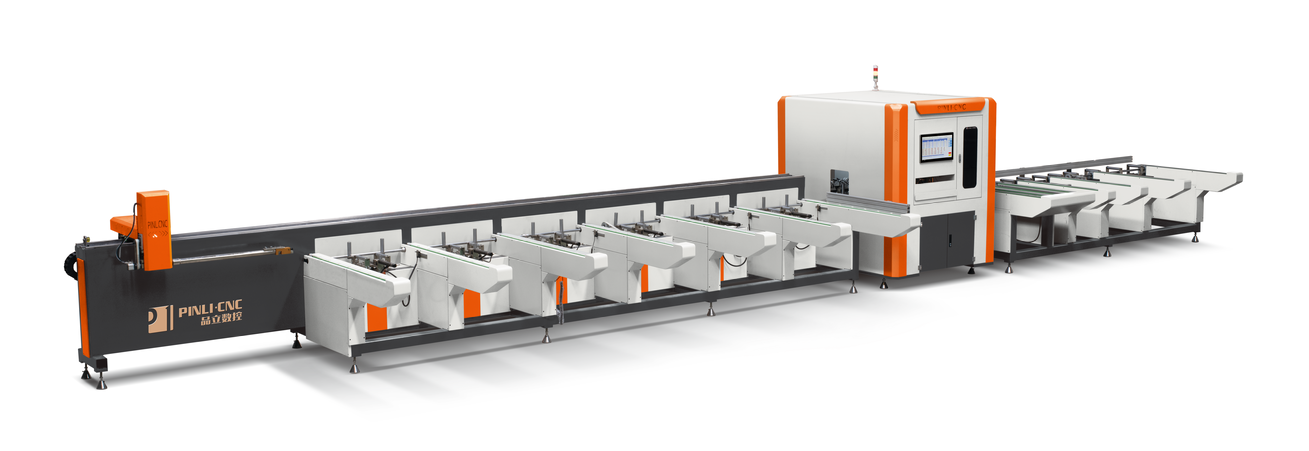

Uses for 45° cutting at both ends of broken aluminum doors and windows profiles and all-aluminum furniture profiles. This equipment has the highest production efficiency and is a new generation of cutting equipment with the most obvious profile saving.

■The left and right machine heads are 45° cutting, which abandons the traditional 90° or arbitrary angle cutting form, and focuses on the 45° cutting of both ends of broken aluminum door and window profiles and all-aluminum furniture profiles. So that the equipment structure is more stable and easy to operate.

■This machine adopts first-line brand control system, bus control and servo absolute value motor. And equipped with an industrial control computer (industrial control computer) to make the equipment run more stably in the harsh production environment for a long time.

■And the main machine feeding frame is processed by vibration aging treatment and large-scale planer, which makes the long-term use of the equipment more stable and precise.

■This machine can realize cutting without material head. Because of manual feeding, the traditional double-head saw must leave 5~10mm material head length. Numerical control feeding can completely avoid the waste of profiles caused by human factors, and cutting each profile can save 5 ~ 10mm. By calculation, the profile can be saved by 1%.

Power supply | 380V/50Hz |

Motor speed | 3000r/min |

Total power of equipment | 13kW |

Saw blade spindle motor | 3kW×2 |

Working pressure | 0.6~0.8MPa |

Air supply | 120L/min |

Cutting length | 150~6500mm |

Cutting width × height | 125×150mm |

Cutting angle | Dual head 45° |

Feeding/Discharge speed | 0~70m/min |

Saw blade specification | Ф500×4.0×3.4×Ф30 Z=120 |

Saw blade feed speed | 0~15m/minStepless adjustable (manual) |

Lubrication and cooling | Automatic lubrication, automatic spray cooling tool |

Overall dimension | 14000×2700×2300mm |

Weight | about 6000kg |

Screenshot, WeChat identification QR code

WeChat ID:RC15954788872

(Click on WeChat to copy and add friends)

We chat